The Challenge

.png?width=900&name=Hiring%20LinkedIn%20Post%20(7).png)

1 min read

The Challenge

A sustainable bulk liquid storage solutions facility had 2 lines going to and from tanks which needed to be changed to renewable diesel feedstock. One was an asphalt line (12” by ~1000-ft horizontal transfer line between storage tanks), and the other was a 6-Oil (fuel oil) line (12” by ~1500-ft transfer line from the tank farm to a railcar loading area).

The lines had to have 100% of the oil completely removed; there couldn’t be any oil with color bodies left that could turn the renewable diesel feedstock dark, as that could make the entire tank off-spec. In the past, the facility would simply remove and replace lines that required a change in service, which resulted in a very large capital project.

Even if the site could replace the pipe, which would have been extremely expensive in itself, the added dilemma remained of having to dismantle equipment chock full of hydrocarbon and then finding a way to transport and/or dispose of it.

The Solution

RTI’s strategy included a proprietary blend of solvent circulation through the lines followed by a vapor phase clean using steam and QuikTurn®. RTI provided a full mechanical rental package as support for hooking up and demobilizing all the equipment, given the lack of maintenance resources available. The facility also did not have Operations, which RTI was able to provide. We also helped to develop new testing methods and metrics for the new application.

RTI helped navigate the diesel soak test with a full 50K-gallon soak by loading 100 gallons of diesel and pigging, then water flushing in the end.

The Results

-

At the onset of the project, the facility had a very difficult time getting any of the product out of the lines. Following RTI's clean, the terminal was able to do a successful water flush of the line and prepared equipment for new service in Renewable Diesel Feed Stock.

-

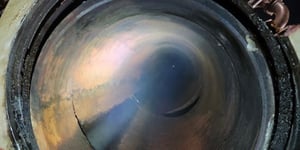

The terminal also cracked a few flanges on the line at the end, near the tanks, and we were able to see that the lines were left with nothing but bare metal.

Related posts

On

The Challenge Concerned about pitting and corrosion, a large Canadian oil sands producer contractedtrue

On

The Challenge Concerned about pitting and corrosion, a large Canadian oil sands producer contractedtrue

On

The Challenge In an Ethylbenzene/Styrene unit, ethylene and benzene are combined to producetrue

On

The Challenge In an Ethylbenzene/Styrene unit, ethylene and benzene are combined to producetrue

.png?width=300&name=Hiring%20LinkedIn%20Post%20(7).png)