The Challenge In an Ethylbenzene/Styrene unit, ethylene and benzene are combined to producetrue

Quick Response Delivers Superior Results in Pipeline Application

1 min read

The Challenge

A Midwest midstream facility was having trouble cleaning a 10-inch line that sends sour fuel from their location to a processing facility a mile and a half away. The sour gas line was scheduled to have maintenance done while the facility that produces the sour fuel was down for turnaround, but with a major highway running over the line and the line owned and operated by separate entities, coordinating the clean was complex.

The process chemical company within the facility where the sour fuel is produced attempted to eliminate the H2S in the line by injecting over 5,000 gallons of H2S scavenger with water but was unsuccessful.

The process chemical company within the facility where the sour fuel is produced attempted to eliminate the H2S in the line by injecting over 5,000 gallons of H2S scavenger with water but was unsuccessful.

The Solution

The facility contacted Refined Technologies to help remove the high levels of H2S that remained. Within 12 hours of receiving the call, RTI was onsite with chemistry, mechanical and injection equipment, and resources ready to execute. After seeing the line packed with heavy solids, RTI requested the line be cleared of all water with a displacement pig, pushed by N2, prior to work starting.

With a water-free line, RTI utilized steam and QuikTurn to vapor phase clean the line. The high-pressure steam, coupled with RTI’s proprietary chemistry and process, not only removed the H2S but also pushed a significant amount of elemental sulfur out of the line into our effluent handling equipment and the facility’s pig-catching equipment.

With a water-free line, RTI utilized steam and QuikTurn to vapor phase clean the line. The high-pressure steam, coupled with RTI’s proprietary chemistry and process, not only removed the H2S but also pushed a significant amount of elemental sulfur out of the line into our effluent handling equipment and the facility’s pig-catching equipment.

The Results

RTI partnered with the client using a combination of traditional methods coupled with strategic chemistry and proprietary processes, achieving great results. The total timeline was 60 hours, from when RTI received the call to when the clean was complete.

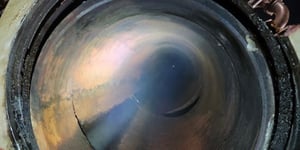

Post application, all gas test readings were 0 (0 ppm H2S, 0% LEL), and much of the solid sulfur had been moved into the pig-catching portion of the pipe with the main trunk down to bare metal clean. The facility was able to complete all necessary repairs to the line without personnel exposures. The line was cleaned to bare metal, completely oil and gas free.

Post application, all gas test readings were 0 (0 ppm H2S, 0% LEL), and much of the solid sulfur had been moved into the pig-catching portion of the pipe with the main trunk down to bare metal clean. The facility was able to complete all necessary repairs to the line without personnel exposures. The line was cleaned to bare metal, completely oil and gas free.

Related posts

On

The Challenge In an Ethylbenzene/Styrene unit, ethylene and benzene are combined to producetrue

On

Industry Challenge The refining industry has a long history of utilizing nitrogen for varioustrue

On

Industry Challenge The refining industry has a long history of utilizing nitrogen for varioustrue

On

The Challenge Concerned about pitting and corrosion, a large Canadian oil sands producer contractedtrue

On

The Challenge Concerned about pitting and corrosion, a large Canadian oil sands producer contractedtrue

.png?width=300&name=Hiring%20LinkedIn%20Post%20(7).png)