The Challenge In an Ethylbenzene/Styrene unit, ethylene and benzene are combined to producetrue

1 min read

The Challenge

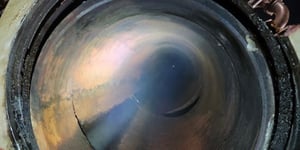

A Gulf Coast pipeline operator contacted RTI when

their compressor station began carrying sludge and “coffee ground” fines mixed with hydrocarbons to the paraffinic compressor circuit, harming their seals and valves and shutting down the compressor.

The facility’s historical approach to open equipment and manually remove foulant from the compressor, piping, and additional equipment would take several weeks. The team wanted a faster and less invasive alternative.

The Solution

RTI put together a rapid response plan, mobilized, and executed a successful vapor phase clean for approximately 500ft of 30” piping containing an inlet and low-pressure separator all within two weeks.

Utilizing effluent capture during the 3-day cleaning

window and keeping the decon in a closed-loop system eliminated environmental exposures and personnel hazards. RTI also supplied the facilities with a full mechanical rental equipment package and third-party mechanical labor to expedite the process.

The Chemistry

RTI utilized a vapor phase application for this clean. The

flare system was used for “heat-up” and frac tanks for

chemical injection effluent. With future applications, RTI recommends two temporary boilers be supplied to expedite heat-up and eliminate the potential for delays.

Under the guidance of RTI, the facility acquired frac

tanks, diesel tanks, water, and vac trucks for the clean.

The Results

All foulants from the piping, lines, and compressor

were successfully removed with vapor phase cleaning and water rinsing. Starting the facilities back up 3 – 4 weeks sooner than anticipated allowed the facility to install new filters, get back online quickly, and run without harming equipment.

Related posts

On

The Challenge In an Ethylbenzene/Styrene unit, ethylene and benzene are combined to producetrue

On

The Challenge A leader in used oil recycling in the Pacific Northwest typically has to plan twotrue

On

The Challenge A leader in used oil recycling in the Pacific Northwest typically has to plan twotrue

.png?width=300&name=Hiring%20LinkedIn%20Post%20(7).png)