The Challenge Historically, this U.S. refiner relied on outside contractors to build their spoolstrue

1 min read

The Challenge

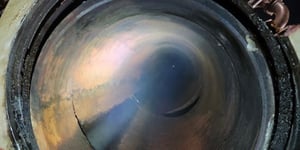

A midstream operator in South Texas experienced paraffinic fouling and 1’ to 2’ of solids/frac sand build up in its inlet separators, as well as in oil and produced water storage tanks. The scope of work included four 2 and 3 stage separators, 14 vertical storage tanks,

compressor suction header and designated piping.

To be proactive and avoid unplanned production interruptions, the operator takes “opportunistic” outages of approximately 6 days to open and manually clean all vessels internally using costly historical methods of water flushing, mucking and potential entry into vessels.

The Solution

RTI uses patented chemicals and processes, coupled with a fleet of purpose-built mechanical equipment and years of operations experience, to prepare production vessels for mechanical work. Vapor phase internal cleaning provides a safer and more economical solution to removing solids, H2S, LEL, paraffinic buildup and hydrocarbon foulants.

The Chemistry

QuikTurn® is a chemistry designed to expedite confined-space entry and clean vessels internally prior to opening. Its hydrocarbon-based formula makes it easy to apply, safe for the environment, and exhibits excellent metallurgy properties.

The Results

RTI’s vapor phase cleaning process and rumble procedures proved to be exceptionally effective on the process equipment, resulting in a timeline savings of 1.5 days as well as a massive reduction in vac truck and water usage. Limited remaining solids were easily washed out or removed with a squeegee.

-

Removed need to air out equipment

-

Approximately 80% reduction in vac truck usage

-

Solids removal timeline on separators reduced by 85%

-

Storage tank cleanup timeline reduced by 90%

-

Waste effluent generation was reduced by 80%

-

Operator redefined “clean” on vessel internals

Related posts

On

The Challenge Historically, this U.S. refiner relied on outside contractors to build their spoolstrue

On

The Challenge A leader in used oil recycling in the Pacific Northwest typically has to plan twotrue

On

The Challenge A leader in used oil recycling in the Pacific Northwest typically has to plan twotrue

.png?width=300&name=Hiring%20LinkedIn%20Post%20(7).png)